Technology description

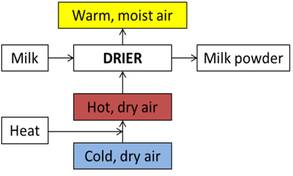

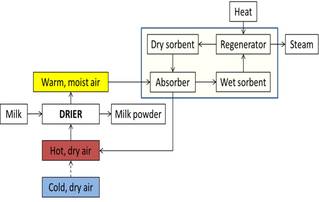

Sorption drying is based on the principle that the absorption of water by a sorbent generates heat. The moisture is absorbed by the sorbent, resulting in dry air and the heat of adsorption heats the air. The hot, dry air can be used again for drying. The difference between a conventional spray drier and a sorption-based drier is shown below. The amount of heat supplied in both systems is equal but the sorption-based system yields an additional flow of steam, where the warm, moist air in the conventional system is released to the ambient.

|

|

|---|

Spray dryer without (left) and with (right) sorption system

Earlier sorption drying systems use zeolite as a solid sorbent. The zeolite is placed in a wheel that can be regenerated using superheated steam, yielding a flow of 1 bar steam to be used in other processes. The advantage is that latent heat in the warm, moist air is recovered in the form of 1 bar steam and also more stable conditions of the drying air can be achieved. However, there are also disadvantages of using a solid sorption material such as:

- There is often a limited need for steam at 1 bar, the required temperatures are often higher – so energy savings are limited or even non-existing;

- Pollution of the sorbent with product particles, especially in combination with regeneration at high temperatures that can cause degradation of the product;

- Entrapment of air in the porous sorbent structure, which is released upon regeneration, making it an unwanted non-condensable in the (steam) system

- The sensible heat losses, when zeolite is heated to regeneration temperature, cannot be easily recovered.

Using a system based on a liquid sorbent rather than a solid sorbent overcomes these problems: similar to the solid sorbent, the liquid sorbent absorbs the water vapor from the warm, moist air resulting in dry, hot air. The diluted sorbent solution can subsequently be pumped to a higher pressure for regeneration and yield, for example, medium pressure steam, often a more desired commodity. The sensible heat losses can be minimized by using liquid-liquid heat exchangers. No air is trapped and pollutions can be filtered out if necessary.